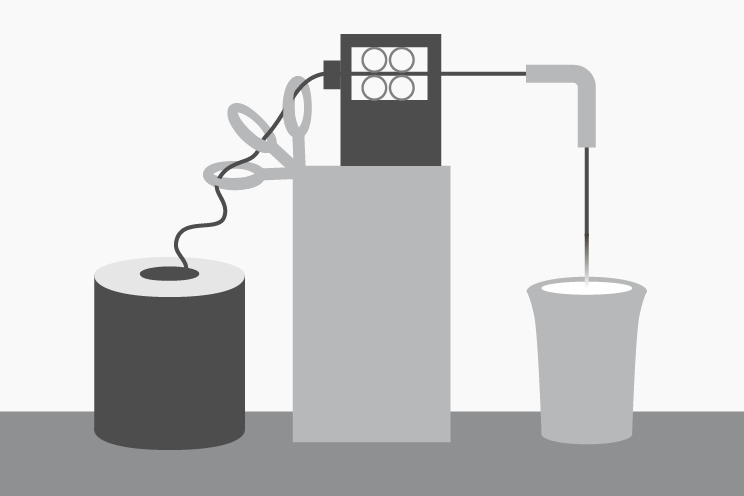

Cored-wire is an additive supply system that can improve quality and contribute to increased productivity during the melting process. A metal pipe is filled with various additives, allowing for precision control over the additive supply during the melting process and stable product quality.

It prevents molten metal surface reactions and enables precision over additives to molten metal, minimizing contamination of oxygen and nitrogen in the air, and improving additive yield. Using a wire feeder ensures stable operation and ease of feeding additives automatically.

Using techniques we have developed over many years of manufacturing additives for the steel industry, we not only develop and produce iron-clad cored-wire, but also products for non-ferrous metals such as copper-clad cored-wire. Our lineup features products that meet the diverse needs of customers, helping improve quality and productivity in a wide range of domains including casting, cast iron production, and copper alloy manufacturing.

OTG provides cored-wire products and offers full support including introducing wire feeder equipment and operational assistance. Our meticulous service encompasses designing, installing, and tuning the optimal system to match your factory environment and meet your manufacturing requirements, providing operational guidance and follow-up service with our expert engineers for smooth operations from start to finish.

Our total solutions are optimized for your production needs, including adjusting product components to tuning equipment controls. Please feel free to contact us for further information.

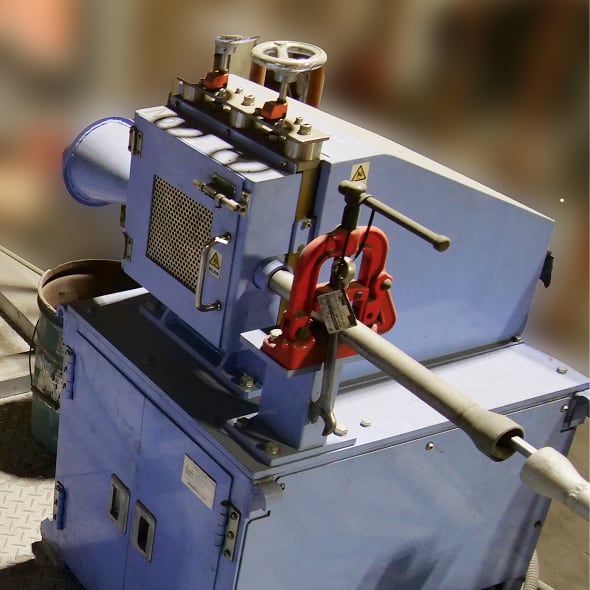

Our wire feeders adapt the supply speed linearly according to

the processed molten metal weight, temperature, and chemical

components, and are equipped with programming functions that

enable precision adjustments to additive amounts. This system

ensures stable quality of cast products at all times.

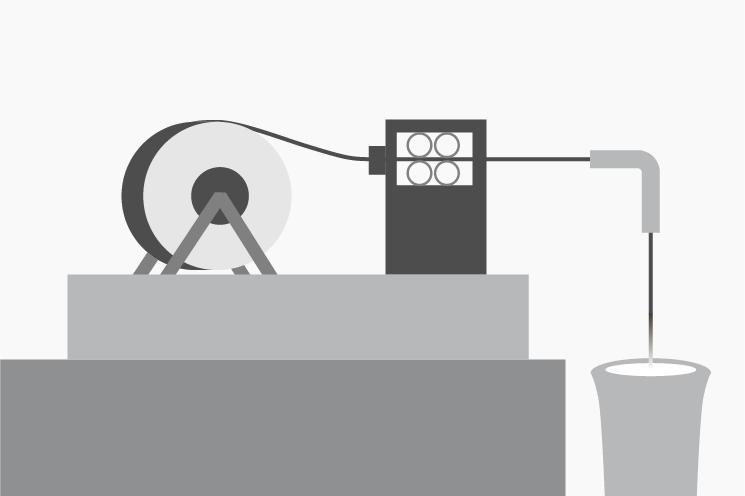

In cases where wire feeding takes considerable time due to large

volumes, multiple wires can be fed into the molten metal

simultaneously to reduce processing times. In addition to

standard specifications, we can also build dedicated user

control programs to your specs (processing patterns, molten

metal process types, process area restrictions, linkage with

other equipment, etc.), helping introduce IoT to your casting

factory. The system also automatically logs wire feeding

processes and errors for your reference.

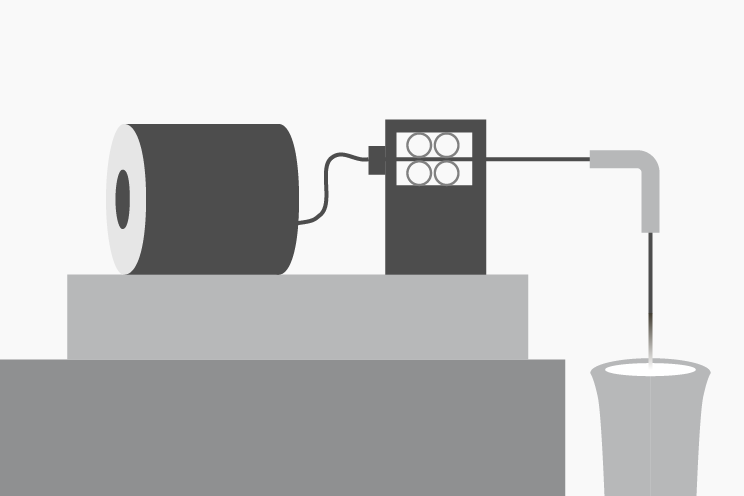

In addition to standard specs, the system can be customized to match your factory environment and manufacturing requirements.

We offer a wide variety of wire types to accommodate various cast products and cast iron products. The filling and wire diameter can be customized, so please feel free to contact us.

| Cladding Material | Available Diameters |

|---|---|

| Iron cladding | Φ 6, φ 10, φ 13, φ 16 |

| Copper cladding | Φ 6, φ 10, φ 13 |

We can provide optimized installation layouts tailored to your factory space.

Automating the additive process can prevent mistakes such as forgetting to add materials in the sandwiching technique, help keep results uniform, stabilize responsiveness, and improve quality. It can also flexibly adapt the optimal additive amount and feeding speed in response to changes in molten metal amounts, sulfur (S) content, and processing temperature, ensuring stable processing.

Processing materials with a lid on the ladle enables localized dust collection, significantly cutting down on dust scattering and smoke, contributing to a better working environment. Reducing the manual workload of adding materials eliminates the need for high-temperature tasks, resulting in improved safety.

Automating additive tasks eliminates the need for manually measuring and adding spheroidizing and covering agents and building dams and pockets, helping reduce the workload and lightening the burden of workers at the furnace. Streamlining ladle bottom processing also increases work precision and efficiency.

Precise control over the amount of additives eliminates wasted raw materials and reduces costs. It also reduces high Mg processes and workloads, saving on labor and reducing overall costs.

Wire processing information is automatically recorded so you can check warning displays when an error occurs and the operating history when needed. This reduces the conventional workload of preparing daily reports and makes traceability much easier.

OTG offers full support from equipment introduction to operations.

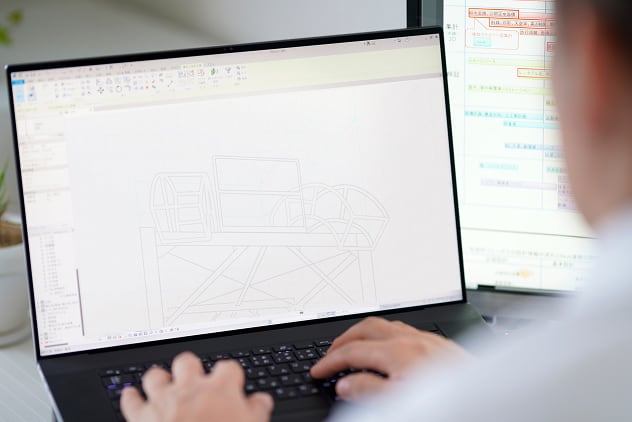

First, we interview customers and collect data on the production environment and product characteristics.

Design the optimal system based on analysis results

Secure installation and tuning by expert engineers

Continued technical support and maintenance after introduction

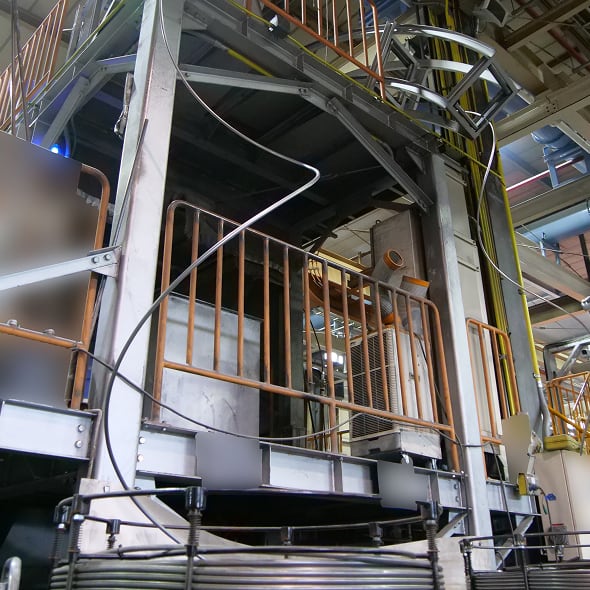

At our factory, demonstration equipment is available so that customers can come in and view the actual cored-wire systems in person. Seeing the equipment in motion up close is an excellent way to visualize system performance and how it would work at your factory. We can also bring the demonstration equipment to your factory and conduct a test before introduction. Please feel free to contact us for details on tours and testing.

If you would like to receive more information or make an inquiry, please contact us via the form below.