In the steel manufacturing process,deoxidizing agents are essential additives for removing oxygen from molten steel and improving its quality and performance. Excessive oxygen in molten steel can result in the formation of non-metallic inclusions which degrade the mechanical characteristics of the product as well as gas defects. The appropriate amount of calcium (Ca) can control the shape of inclusions and improve the quality of the steel. Our deoxidizing agent additive lineup consists of a variety of components and forms,offering the optimal deoxidizing effects for your steel manufacturing process.

| Product | Explanation |

|---|---|

| Ca-Si | Deoxidizing agent that contains mainly calcium (Ca) and silicon (Si) which contributes to the purification of steel and improved performance. |

| Fe-Ca-Si | Compound deoxidizing agent that contains iron (Fe), calcium (Ca), and silicon (Si), offering a milder reaction than Ca-Si that is easier to control and produces superior solubility for molten steel. Also effective for controlling the shapes of non-metallic inclusions. |

| Ba-Ca-Si | High-performance compound deoxidizing agent that contains barium (Ba), calcium (Ca), and silicon (Si). The addition of Ba helps suppress responsiveness during the molten metal phase and control inclusion shapes, improving the purity and mechanical properties of steel. |

| RE-Ca-Si | Deoxidizing agent that contains rare earth elements (RE), calcium (Ca), and silicon (Si). The addition of RE helps maintain the deoxidizing effects for a long period of time, shrinks non-metallic inclusions, and achieves superior uniform distribution. |

| Al-Si-Fe | Deoxidizing agent whose main components are aluminum (Al), silicon (Si), and iron (Fe), offering both powerful deoxidizing performance and economic efficiency. Particularly suited to high-temperature deoxidization. |

| Ni-Mg | Nickel (Ni) and magnesium (Mg) alloy deoxidizing agent. Delivers stable deoxidization effects and a high level of safety and is particularly suited to high alloy steel and special steel manufacturing. |

| Ni-Ca | Nickel (Ni) and calcium (Ca) alloy deoxidizing agent. Because it takes advantage of calcium’s high compatibility with oxygen and does not contain silicon (Si), it can be used to deoxidize high nickel-chromium steel. |

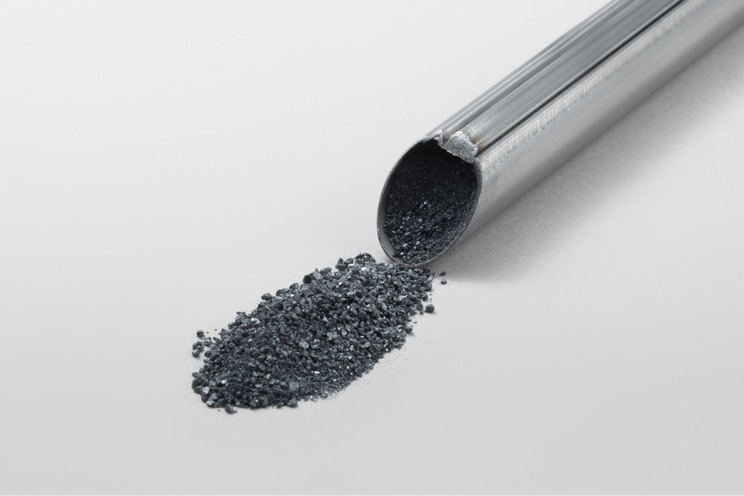

Wire deoxidizing agent or Ca additives are rational techniques for adding precise amounts of Ca to molten steel. Filling a hollow cladded wire with additive and feeding it into molten steel via automatic controller delivers a higher yield and uniform quality compared to conventional clump additive processes.

Components are examples of representative products. We may be able to make adjustments to meet your needs, so please feel free to contact us.

| Product | Filler Components | Cladding | Diameter |

|---|---|---|---|

| Ca-Si wire | Ca:30%, Si:60%, Fe:Bal. | Fe | φ10, φ13, φ16 |

| Ca wire | Ca:Over98% | Fe | φ10, φ13 |

| Ca-Fe wire | Ca:30%, Fe:Bal. | Fe | φ10, φ13 |

| Ca-Fe-Al wire | Ca:40%, Al:30%, C:<1%, Fe:Bal. | Fe | φ10, φ13 |

| Mg wire | Mg:99.9% | Cu | φ10, φ13 |

| Cu-Zr wire | Zr:47-53%, Cu:Bal. | Cu | φ10, φ13 |

If you would like to receive more information, please contact us via the form below.