Products

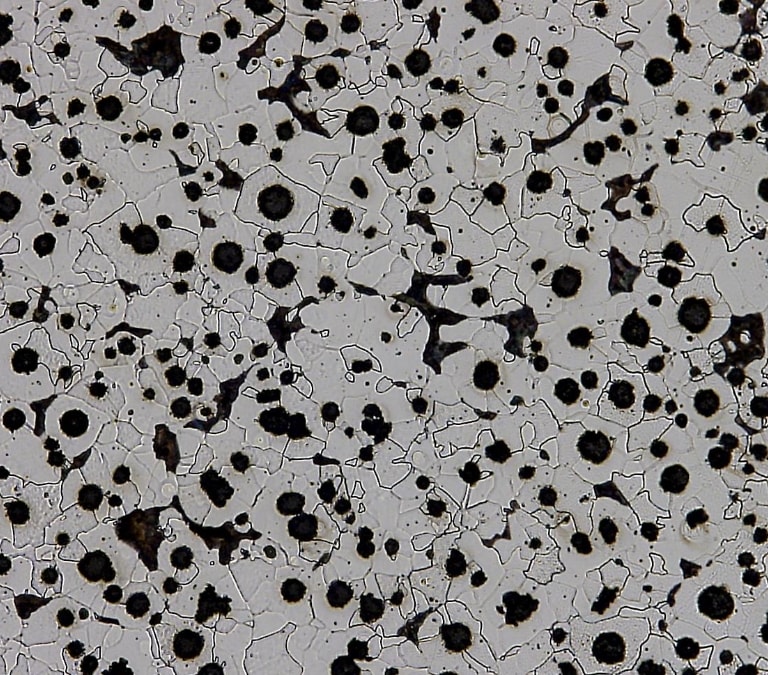

Since the establishment in the early days of ductile cast iron, we have accumulated the data on processing technology of molten metal under various conditions which are provided by a number of foundries throughout Japan, as an exclusive manufacturer of additives for molten cast iron processing.

Based on the vast data, we have developed additives for molten metal processing to meet the various needs of users, and have maintained the highest market share in the industry up to the present.

The high-quality alloys manufactured in Japan will be the best partner in your casting works with the support of our fine after-sales service for their use. We are not just selling additives, but also proposing optimal methods of molten metal processing and alloy compositions.

Please feel free to contact us.

Ferro alloy

Globurizing Additives

Inoculants

Additives

Mother alloy

Ni-based mother alloy

The application of this mother alloy is not limited to cast iron, but is expanding as an additive for special deoxidizers for nickel alloys and alloys for magnetic materials. Nickel-calcium mother alloy is also one of our core products as a deoxidizer for special steels and we are the one and only manufacturer in Japan.

Alloying nickel having a high melting point with active metals such as magnesium and calcium requires a high level of knowledge and technology, as well as continuous effort for quality improvement in order to meet the target range of each ingredient required by users.

Accumulation of such efforts and experience is utilized in the alloying with low-melting-point elements and also high-melting-point elements such as cobalt, titanium and molybdenum, resulting in further expanding the sales channels.

Cu-based mother alloy

Therefore, many mother alloys are used. We are manufacturing mainly deoxidizing mother alloys containing calcium and magnesium and other mother alloys such as zirconium, titanium, iron, etc. which are used as crystal refining agents.

The mother alloy for stable adding of chromium etc. to molten copper to improve the strength is also one of our core products.

Copper is a metal that has high oxygen dissolution during the dissolution process, and for that reason, some metals are very difficult to alloy with. Therefore, we are manufacturing homogeneous and segregation-free mother alloys by techniques including melting atmosphere adjustment and deoxidation.

Al-based mother alloy

We are also manufacturing the mother alloy for titanium adding that is necessary to refine crystals and prevent casting defects such as shrinkage cavities. In addition, we have offered a number of custom-made products from the fields other than aluminum die casting and aluminum gravity casting.

Aluminum is a metal with an extremely effective deoxidation effect. We are willing to work as much as possible for the experiment of a mother alloy as a deoxidizer for steel and all other metals.

Zn-based mother alloy

Including the mother alloy for stable adding of titanium or copper used to improve the properties of zinc die-cast products, the manufacture of special mother alloys to satisfy the extremely complex and severe properties required for plating is our specialty.

Zinc is an element that has a property of evaporating at low temperature, and therefore requires a delicate melting operation depending on the targeted metal.

We have adopted unique solutions on our melting and casting facilities and are offering high-quality mother alloys.

Cored wire

Cored wire for steelmaking

Cored wire for iron casting

Cored wire for non-ferrous metals

Other

Pig iron

Sorelmetal

Chemical products

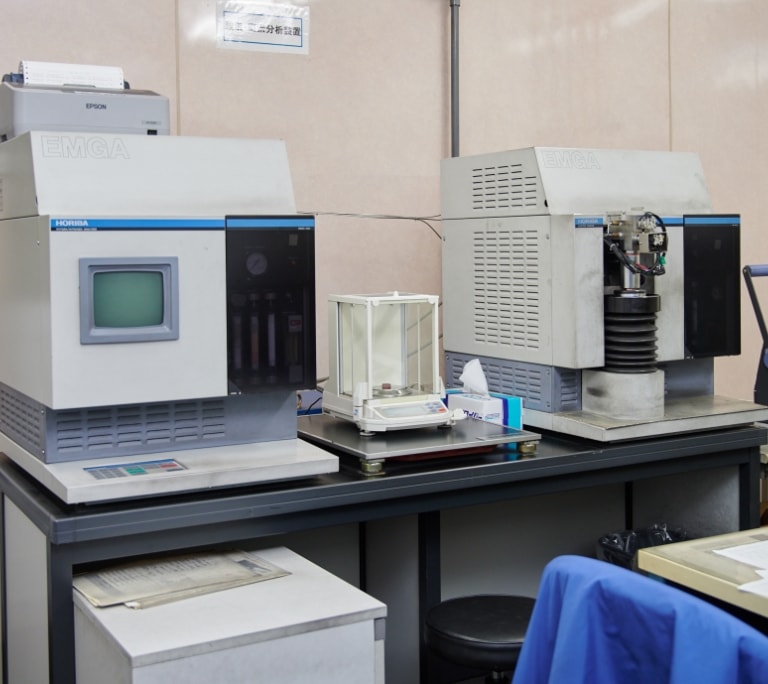

Quality control system

We are controlling the quality of products under a well-prepared system with the latest equipment.